-

Congratulations to TORCH for winning the 2021 China International Automotive Regulatory Power Device Packaging Service Annual High Quality Supplier Award

Date: 2021-11-5

At the 2021 China International vehicle specification level power semiconductor annual conference held from November 4 to 5, 2021, TORCH won the 2021 China International vehicle specification level power device packaging service annual quality supplier award

-

TORCH Jiangsu Company’s First (Set) High-End Packaging Equipment Launched off Assembly Line

Online vacuum reflow furnace V8H, as the first product launched off assembly line of TORCH Jiangsu company, not only has superior data performance, but also has a number of patent innovations. It is an excellent domestically produced product in the field of China's semiconductor packaging equipment.

-

I'll Tell You Something About Vacuum Heat Treatment

Date: 2019-12-28

Vacuum annealing: eliminate and reduce the heterogeneity of tissue, remove internal stress and improve its plasticity.

Vacuum tempering: eliminates internal stress during machining.

Vacuum quenching: (gas quenching, oil quenching) fast cooling after heating to harden the material.

Vacuum carburizing: carburizing is performed in vacuum heating and in a negative pressure carburizing atmosphere.

Vacuum ion carburizing: a new vacuum chemical treatment for hardening of metal surfaces. -

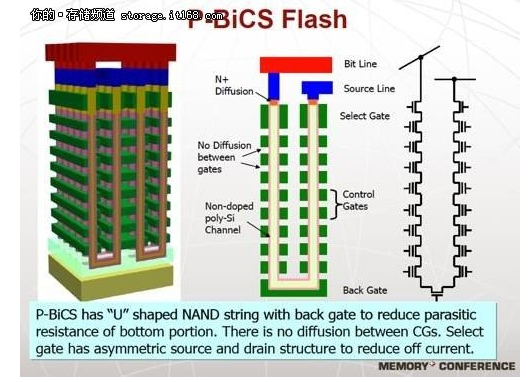

Solve the Problem of 3D Chip Stack and Break the Limit of Moore's Law

Date: 2019-12-28

To solve the problem of liquid cooling when 3D chips stack, the defense advanced research projects agency (DARPA), in collaboration with IBM and the Georgia institute of technology, has developed an in-chip/inter-chip enhanced cooling program that USES an insulating dielectric refrigerant (instead of water).

-

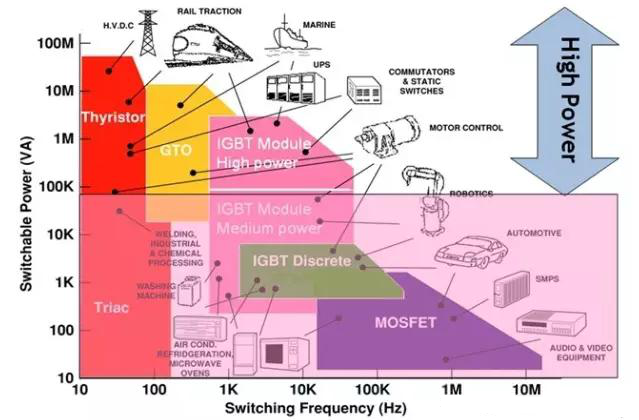

Technical Status and Characteristics of High Power IGBT Chip

Date: 2019-12-27

This paper respectively from the IGBT chip structure, the structure of the collector area on the back and front MOS structure, the system analyzes the technology present situation and the characteristics of high power IGBT chip, from two aspects of chip welding and the electrode interconnection comprehensive IGBT module encapsulation technology is introduced, and the new structure, new technology and new materials technology three aspects analyzes the IGBT technology the development direction of the future.

-

Five Applications of High Power Semiconductor Lasers in Industrial Fields

Date: 2019-12-27

With the development of semiconductor chip technology and optical technology, the output power of semiconductor lasers has been continuously improved, the beam quality has been significantly improved, and more applications have been obtained in the industrial field.

At present, the output power and beam quality of industrial high-power semiconductor lasers have exceeded that of lamp pumped YAG lasers and are close to that of semiconductor pumped YAG lasers. -

UVLED is Mainly Used in Various Bands

Date: 2019-12-26

UVA light curing principle: add light initiator in a specially formulated resin (or photosensitizer), after absorption in the ultraviolet (UV) light curing equipment after high intensity of ultraviolet light, active free radicals or ion, causing polymerization, crosslinking and grafting reaction, the resin (UV coating, printing ink, adhesive, etc.) in seconds (range) from liquid into solid.

-

Why Use Vacuum Welding Process at MiniLED?

Date: 2019-12-26

In recent years the rapid development of the panel industry, after the domestic manufacturers crazy expansion, the product supply and demand relationship has been basically relaxed, manufacturers began to focus on the product "quality" to improve.

The display panel industry is moving toward high-resolution graphics, curved surfaces, ultra-thin surfaces, thinness, bendability, high dynamic HDR, high contrast and wide color games. the mini-led is born. -

Introduction of Vacuum Sintering Process

Date: 2019-12-24

1. Working principle:

Vacuum sintering is a process of forming (finished and semi-finished) powder and block materials.

The basic process is: the sintered material (powder or block) is placed in the vacuum furnace, the door is closed and the furnace is vacuumized.

The furnace vacuum is pumped to the required working vacuum (generally 3×10-3 Pa), which is immediately inflated to complete the whole sintering process. -

Toshiba's 3D Chip Stack Strategy: Build Flash Memory Like a Building

Date: 2019-12-24

Toshiba is building high-level flash memory and ReRAM chips, and prototype samples are expected to be launched next year.

The idea of a high-rise or 3D chip is that we can bypass the limitations of the increased density of flash or memory chips and stack them up to increase the storage density, just as a high-rise house can accommodate more people. -

What is Vacuum Brazing? What Are the Characteristics of Vacuum Brazing?

Date: 2019-12-23

Principle of operation brazing is the use of a material with a lower melting point than the base metal as the filler when two materials of the same or different properties are connected.

When the connected part and the filler are heated to the point where the filler melts, the liquid filler is used to moisten and capillary flow in the surface gap of the base metal, and then it dissolves and diffuses with the base metal to achieve the connection between the connected parts. -

What Is the Process Atmosphere Environment of the Vacuum System?

Date: 2019-12-21

In the application of vacuum system, the extracted gas not only includes the various gases generated in the application process, but also includes the original atmosphere and air in the system, etc., then, what are the total?

-

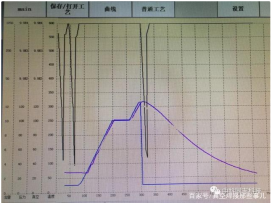

Difference Between Vacuum Vapor Reflow Welding and Hot Air Reflow Welding

Date: 2019-12-16

The difference between gas phase reflow welding and hot air reflow welding is that gas phase reflow welding USES vapor phase liquid to heat the key.

Vapor phase reflow welding process has many advantages over other reflow welding methods, mainly in the following aspects: high temperature control accuracy, high temperature uniformity, and relatively low oxygen content control, can be used in a low oxygen environment for welding. -

The Principle of Vacuum Soldering System is Explained in This Paper

Date: 2019-12-16

Vacuum soldering system is a kind of process welding furnace for high-end products, such as laser devices, aerospace, electric cars and other industries, compared to the traditional chain furnace, has great technical advantages.

The main components of the vacuum eutectic furnace system include: vacuum system, reduction atmosphere system, heating/cooling system, gas flow control system, safety system, control system, etc. -

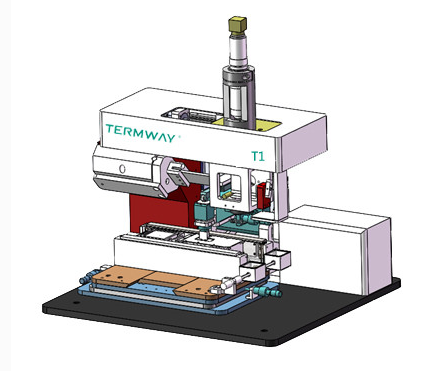

Submicron Semi-automatic Flip Eutectic Placement Machine Flip Eutectic Placement Machine

Date: 2019-12-16

T1 is a multi-function placement machine, also a submicron flip eutectic placement machine, providing placement accuracy up to 5 microns, suitable for all kinds of flip chip, common chip mounting, can handle the minimum chip spacing as low as 50 microns.

This universal SMD platform is suitable for a wide range of microassembly applications, covering almost all microassembly SMD processes, and can even be configured as cutting-edge FC/SMD repair systems. -

Why Do We Pay Attention to IGBT?

Date: 2019-12-16

IGBT is the core device of energy conversion and transmission and the "CPU" of power electronic devices.

Using IGBT for power transformation can improve the efficiency and quality of electricity use, and is featured by high efficiency, energy saving and green environment protection. It is the key supporting technology to solve the problem of energy shortage and reduce carbon emission. -

TORCH Vacuum Reflow Oven Appears in China International Information and Communication Exhibition

Date: 2019-12-16

Hosted by the ministry of industry and information technology, ciict is one of the largest and most influential ICT events in Asia.

With a history of more than 28 years since 1990, icict has been committed to building the most influential and innovative ICT platform, providing comprehensive services, communication and cooperation opportunities, including policy interpretation, technology research and development, market application and financial investment, for the ICT industry chain. -

What Is A Vacuum Reflow Oven? What is The Difference Between Vacuum Reflow Welding and Vacuum Reflow Welding?

Date: 2019-12-16

Vacuum reflow oven is to conduct high-quality welding for products in a vacuum environment to protect products and solder from being oxidized under the condition of vacuum, and to react the oxide of products and solder surface at the same time to improve the quality of welding surface and reduce the void rate of welding.

Generally used in aerospace, medical, automotive and other high-precision products. -

What Is A Vacuum Reflow Oven? What Are The Categories?

Date: 2019-12-16

Vacuum reflow solder is refers to the vacuum eutectic oven, vacuum in vacuum environment for high quality welding products, in the welding process of zhongtong into reducing system (N2, formic acid, N2H2, H2), to protect the product and the solder is not oxidized, at the same time the product and solder oxide on the surface of the reaction, make weld surface quality improvement, reduced the rate of welding hollow.

-

How to Tmprove The Reliability of Superpower Lasers

Date: 2019-12-16

Superpower lasers are characterized by small size, light weight, high electro-optic conversion efficiency, stable performance, high reliability and long life.

At present, the low-power laser and the medium-power laser are gradually being localized, while the superpower lasers are just beginning to be localized and is accelerating.

How to Tmprove The Reliability of Superpower Lasers welding is an urgent technical problem.

The sharp increase of laser power will lead to the decrease of its reliability and shorten its working life. -

The Vacuum Oven Used for Automobile Headlights Has A Vacuum Rate of 0%

Date: 2019-12-16

In recent years, the automotive industry headlights using LED, especially the of large power LED chip more and more.

Especially in the headlamp part of the large hernia lamp with high-power high-power LED panel, the effect is very good.

However, it also brings the reliability problem of LED chip. In order to improve the reliability, high-power LED chip is used in the automotive LED field, and vacuum reflow welding is used for high-power LED chip. -

UVLED Application Burst Buffer Period, The Urgent Matter of The Moment Is to Start The Technical War

Date: 2019-12-16

In recent years, as a subdivision of the LED industry, UV LED industry has developed in full swing.

In 2019, the UV LED industry is in the buffer phase of application explosion, and the most urgent task for relevant companies is to launch the technology war, in order to capture as many places as possible before the real market explosion. -

Why Are Lasers So Awesome? Because of Our Vacuum Sintering Oven Auxiliary!

Date: 2019-12-13

The industrial chain of laser processing has formed a complete ecological chain of laser processing from enterprises producing core lasers upstream to enterprises producing various kinds of laser processing equipment and then to enterprises providing laser processing services.

With its excellent processing performance and high efficiency, more and more laser processing equipment can be seen in the production of various advanced manufacturing industries. -

Vacuum Reflow Welding Technology of UVLED Chip Package Welding Is Introduced

Date: 2019-12-12

The emergence of UVLED is a revolutionary change in the UV curing industry. Its constant light intensity, excellent temperature control, environmental friendly and portable, it is widely used in communication, electronics, optics, printing, medical and other fields.

UV curing, mainly using mercury lamp irradiation as the mainstream of the production process, not only pollution of the environment, and the traditional UV lamp high energy consumption, short service life.

- Home

- News